- SS/SSBSeries three-legged m...

- PS/PSF(GMP)Series Flat Top ...

- Series Flat Top Discharge C...

- PD/PDFSeries flat bag type ...

- PAUT/AUTSeries Suspension S...

- Flat automatic scraper lowe...

- SG/SGZSeries scraper lower ...

- SSCThree-legged sedimentati...

- LW/LWLSeries Horizontal Scr...

- 200Desktop small experiment...

- PD1250Flat bag lifting and ...

- Three-legged manual unloadi...

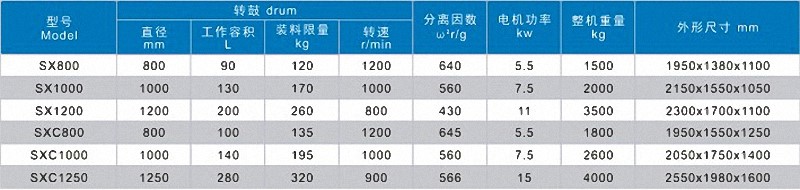

- SX/SXCSeries lower discharg...

- Centrifuge accessories

phone:86-0512-58662585

Fax:86-0512-58660959

Contact:Mr Mao

Mobile phone:013906246830

E-mail:leyujd@163.com

website:www.leyujd.com

Product features and uses

The SX type three-legged centrifuge is a manual lower discharge, intermittent operation filter centrifuge. It is suitable for separating a suspension containing a solid phase (granular, crystalline or short fibrous) concentration of 5 to 60% and a particle size ranging from 0.5 to 1.5 mm. The series of centrifuges have simple structure and operation, and the operation steps can be adjusted as required. The filter residue can be fully washed, the solid phase is not easy to be damaged, and the adaptability is strong. Because it is the lower discharge, the labor intensity is reduced. Used in chemical, light industry, food, pharmaceutical, metallurgical and other industries.

SXC is a three-legged lower manual discharge sedimentation centrifuge. The centrifuge drum of this series is a non-porous wall and belongs to a settling drum. The centrifuge has the advantages of simple structure, reliable performance, convenient operation and maintenance, and the like, and is mainly suitable for fine viscous materials and solid-liquid separation occasions in which regeneration of the filter material is difficult.

download Google

For different separation requirements, we have designed the corresponding type for the customer to choose, so when the customer orders: can confirm the following

Material: The material in contact with the material can be divided into stainless steel, titanium, carbon steel, rubber lining, lining plastic and so on.

Drive mode: ordinary asynchronous motor, flameproof asynchronous motor or electromagnetic speed control motor or frequency control.

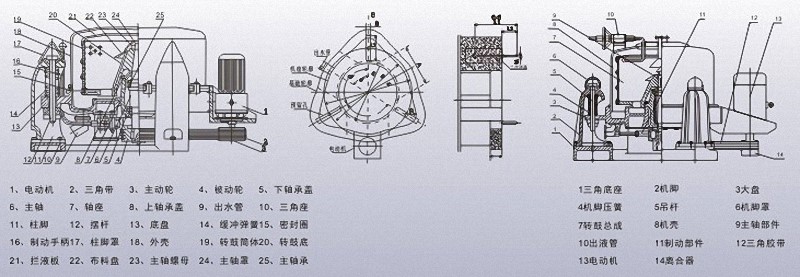

Product structure diagram

Structure and principle

The speed regulating motor drives the rotating drum to rotate, adjusts the speed to the medium speed, and the material is evenly sprinkled from the upper part to the rotating edge cloth disc to the drum wall, and rises to high speed. Under the action of centrifugal force, the liquid phase air filter cloth and the drum wall filter hole Discharge, the solid phase is trapped in the drum, and the filter bag is manually removed or shaken after the machine is stopped, so that the solid phase is loosened and discharged from the lower part.

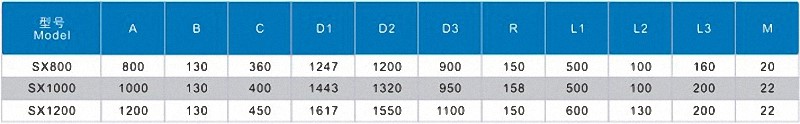

Basic installation size